In global industrial projects, you will encounter two major flange standards: DIN and ANSI. They are not the same. Knowing the differences is crucial because they are generally not interchangeable. Using the wrong one can stop your project.

This guide explains the key differences to help you choose the right standard.

Core Differences at a Glance

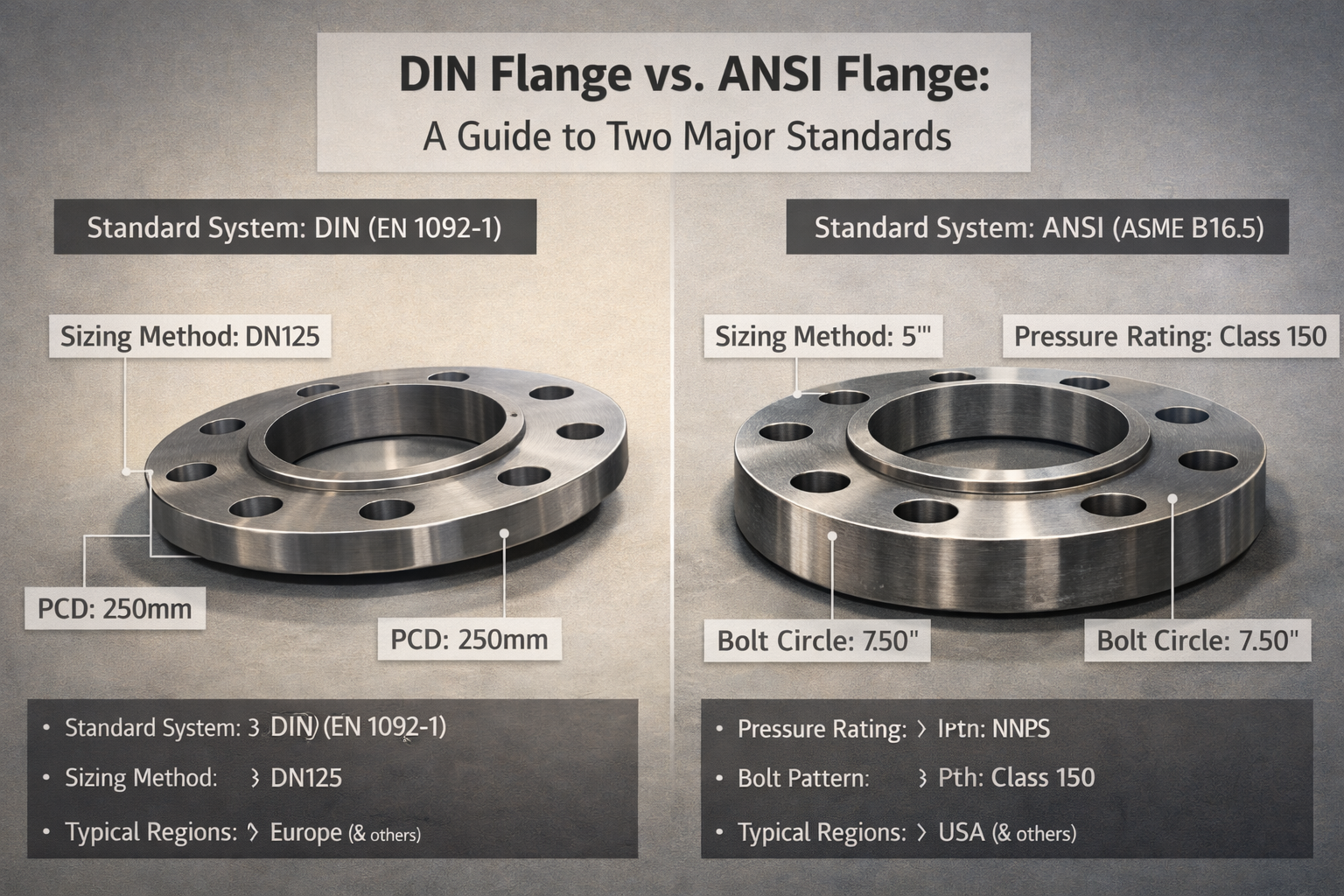

DIN and ANSI flanges differ in their origin, measurement system, and pressure ratings. This table summarizes the main points.

| Feature | DIN Flange (European Standard) | ANSI Flange (American Standard) |

| Origin & Standards | German Institute for Standardization (DIN). Common standards are DIN 2501, DIN 2632-2638, and the newer EN 1092-1. | American National Standards Institute (ANSI), now maintained by ASME. The key standard is ASME B16.5 (or the older ANSI B16.5). |

| Measurement System | Metric (mm). All dimensions are in millimeters. | Imperial (inches). All primary dimensions are in inches. |

| Pressure Rating System | PN (Pressure Nominal). Common ratings are PN6, PN10, PN16, PN25, PN40. The number refers to pressure in bars at 20°C. | Class. Common ratings are Class 150, 300, 600, 900. The number is a pressure-temperature rating, not a direct PSI value. |

| Bolt Holes | Bolt holes are typically not drilled into the flange. They are tapped threads for metric bolts. | Bolt holes are drilled through for using stud bolts and nuts. |

| Common Applications | Common in Europe, the Middle East, Asia, and in industries following European equipment designs (chemical, water). | Predominant in the United States, Canada, and many oil & gas and refining projects worldwide. |

| Gasket Type | Often used with a full-face gasket that covers the entire flange face, including the bolt holes. | Typically uses a ring gasket that sits inside the circle of bolt holes. |

Key Takeaway: The most obvious visual difference is the bolts. A DIN flange uses bolts that screw into the flange itself. An ANSI flange uses stud bolts that pass through holes and are secured with nuts on the back.

Pressure Ratings: PN vs. Class

This is a major point of confusion. You cannot directly match a PN number to a Class number.

- A PN16 flange is often considered roughly equivalent to an ANSI Class 150 flange in terms of pressure capacity at low temperatures.

- However, the pressure-temperature curves are different. The actual maximum working pressure for each depends on the material and temperature. You must check the rating tables for each standard.

- PN ratings (6, 10, 16, 25, 40) do not scale evenly. Class ratings (150, 300, 600, 900) do scale, a Class 300 flange is rated for roughly twice the pressure of a Class 150 flange at the same temperature.

Are DIN and ANSI Flanges Interchangeable?

No, they are not directly interchangeable.

You cannot bolt a DIN PN16 flange to an ANSI Class 150 flange, even if they are for the same pipe size. The reasons are:

- Different Dimensions: The outside diameter, bolt circle diameter, and number of bolts are all different.

- Different Bolt Systems: One has threaded holes, the other has through-holes.

- Different Gaskets: A full-face gasket for a DIN flange will not fit an ANSI flange’s raised face.

If you need to connect them, you must use an adapter spool or a specially designed transition flange. This is a custom part with a DIN face on one side and an ANSI face on the other.

How to Choose the Right Standard

Your choice is usually dictated by the project or existing equipment. Follow this decision logic:

- Check Existing Equipment: Look at the flange you need to connect to. Does it have tapped bolt holes (DIN) or through-holes (ANSI)? What is marked on it (PN or Class)?

- Follow Project Specifications: The engineering drawings or client requirements will state the governing standard (e.g., “ASME B16.5” or “EN 1092-1”).

- Consider Location: Projects in Europe commonly use DIN/PN standards. Projects in North America or global oil and gas typically use ANSI/ASME.

Frequently Asked Questions

Q: What if my old drawings say “ANSI B16.5”?

A. That is the old designation. The standard is now ASME B16.5. The dimensions and ratings are identical. You can safely use a modern ASME B16.5 flange.

Q: Is DIN 2501 still used?

A. The older DIN standards (2501, 2632, etc.) have largely been replaced by the harmonized European standard EN 1092-1. However, the core dimensions for PN ratings remained very similar. A PN16 flange today is made to EN 1092-1.

Q: Can I convert dimensions from inches to mm to make them fit?

A. No. Simple conversion does not work. The standards have completely different dimensional series. A 6-inch ANSI flange and a DN150 (6-inch) DIN flange have different bolt circles and hole counts.

Q: Which standard is stronger?

A. Neither is inherently stronger. Both standards produce flanges suitable for their rated pressures. The choice is about system compatibility, not a general statement of quality.

Q: What does “DN” mean?

A. DN (Diameter Nominal) is the metric equivalent of NPS (Nominal Pipe Size). DN 100 is roughly equivalent to NPS 4. Like the flanges themselves, the pipes are not directly compatible due to different outer diameters.

Conclusion

DIN and ANSI flanges are two different languages for the same purpose: connecting pipes. You must use the correct “language” for your system. The choice is typically not yours—it is dictated by the equipment you are connecting to or the geographic location of the project. Always verify the standard, the pressure rating (PN or Class), and the specific dimensions before ordering.

Need to connect systems with different flange standards or source flanges for an international project? We have experience with both DIN/PN and ANSI/ASME specifications and can provide the correct components or adapter solutions. Submit your project details for expert guidance on flange standards: http://texasflange.com/lp12/